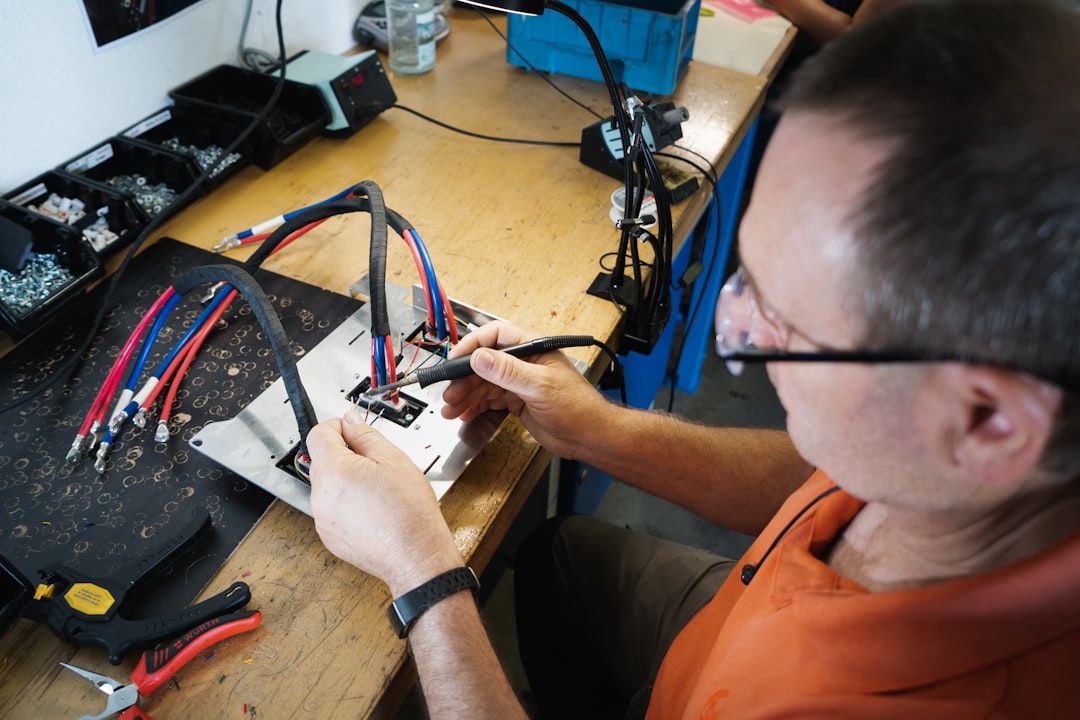

Wire stripping machines are essential tools in industrial operations that involve the handling and processing of electrical wires and cables. These machines are designed to efficiently and accurately remove the insulation from the metal conductors of wires, allowing for the recycling of valuable copper and aluminum materials. Wire stripping machines come in various types and sizes, ranging from manual hand-cranked models to fully automatic machines with advanced features.

The use of wire stripping machines has become increasingly popular in industries such as electrical contracting, construction, telecommunications, and recycling. These machines offer a cost-effective and time-saving solution for processing large volumes of wires and cables, while also reducing the risk of injury and improving overall productivity. In this article, we will explore the benefits of using wire stripping machines, the different types available, how to choose the right machine for your industrial operation, tips for efficient operation, and maintenance and safety considerations. We will also discuss future trends in wire stripping machine technology and how it is shaping the industry.

Key Takeaways

- Wire stripping machines are used to remove insulation from electrical wires, making the process faster and more efficient.

- Using wire stripping machines can increase productivity, reduce labor costs, and improve the quality of wire-stripping work.

- There are different types of wire stripping machines available, including manual, electric, and pneumatic models, each with its own benefits and limitations.

- When choosing a wire stripping machine for industrial operations, factors such as wire size, production volume, and budget should be considered.

- To ensure efficient operation of wire stripping machines, proper training, regular maintenance, and safety precautions are essential.

Benefits of Using Wire Stripping Machines

The use of wire stripping machines offers a wide range of benefits for industrial operations. Firstly, these machines significantly increase efficiency and productivity by automating the process of removing insulation from wires and cables. This allows for a higher volume of materials to be processed in a shorter amount of time, ultimately leading to cost savings and improved profitability for businesses. Additionally, wire stripping machines help to reduce the risk of repetitive strain injuries and other work-related health issues that can arise from manual wire stripping processes.

Furthermore, wire stripping machines contribute to environmental sustainability by enabling the recycling of valuable copper and aluminum materials. By efficiently removing the insulation from wires and cables, these machines make it possible to recover and reuse the metal conductors, reducing the need for new raw materials and minimizing waste. This not only benefits the environment but also helps businesses to meet sustainability goals and regulations. Overall, the use of wire stripping machines offers a range of economic, ergonomic, and environmental benefits for industrial operations.

Types of Wire Stripping Machines

There are several types of wire stripping machines available on the market, each designed for specific applications and operational requirements. Manual wire stripping machines are operated by hand and are suitable for small-scale operations or occasional use. These machines are often compact and portable, making them ideal for on-site work or workshops with limited space. Manual wire stripping machines are typically affordable and easy to use, making them a popular choice for small businesses and DIY enthusiasts.

On the other end of the spectrum, automatic wire stripping machines are designed for high-volume industrial operations that require consistent and precise wire-stripping capabilities. These machines are equipped with advanced features such as programmable controls, adjustable cutting depths, and automatic feed systems, allowing for efficient processing of large quantities of wires and cables. Automatic wire stripping machines are often used in recycling facilities, manufacturing plants, and other industrial settings where speed, accuracy, and reliability are essential.

In addition to manual and automatic models, there are also semi-automatic wire stripping machines that offer a balance between manual control and automated functionality. These machines are suitable for medium-sized operations that require a higher level of productivity than manual machines can provide but do not justify the investment in a fully automatic system. Semi-automatic wire stripping machines are versatile and can be adjusted to accommodate different wire sizes and insulation types, making them a practical choice for a wide range of applications.

How to Choose the Right Wire Stripping Machine for Your Industrial Operation

| Factors to Consider | Importance |

|---|---|

| Wire Diameter | High |

| Stripping Speed | High |

| Wire Material | High |

| Automation Level | Medium |

| Footprint | Medium |

| Cost | Low |

When selecting a wire stripping machine for your industrial operation, it is important to consider several factors to ensure that you choose the right machine for your specific needs. Firstly, you should assess the volume of wires and cables that you need to process on a regular basis. If you have a high volume of materials to handle, an automatic wire stripping machine with a high processing capacity would be the most suitable option. Conversely, if your operation involves smaller quantities of wires or occasional use, a manual or semi-automatic machine may be more appropriate.

Another important consideration is the type and size of wires that you will be working with. Different wire stripping machines are designed to accommodate various wire gauges and insulation types, so it is essential to choose a machine that can effectively handle the materials you work with. Additionally, consider the available space in your facility and whether portability is a priority for your operation. Some wire stripping machines are compact and portable, while others are larger and more stationary, so it is important to select a machine that fits your workspace and operational requirements.

Furthermore, it is crucial to evaluate the level of automation and control that you require from a wire stripping machine. Automatic machines offer advanced features such as programmable controls and automatic feed systems, while manual machines provide more hands-on control over the stripping process. Consider your operational preferences and the skill level of your workforce when choosing between manual, semi-automatic, and automatic wire stripping machines. By carefully assessing your processing needs, material specifications, space limitations, and operational preferences, you can select the right wire stripping machine to optimize efficiency and productivity in your industrial operation.

Tips for Efficient Operation of Wire Stripping Machines

To ensure efficient operation and maximize the performance of wire stripping machines, there are several tips that industrial operators should keep in mind. Firstly, it is important to properly set up the machine according to the specifications of the wires being processed. This includes adjusting cutting depths, feed rates, and other parameters to ensure accurate and consistent results. Proper machine setup is essential for achieving high-quality wire-stripping outcomes while minimizing material waste.

Additionally, regular maintenance and cleaning of wire stripping machines are crucial for optimal performance. This includes keeping cutting blades sharp, lubricating moving parts, and removing debris or buildup from the machine’s components. By maintaining the machine in good condition, operators can prevent premature wear and tear, reduce downtime due to malfunctions, and extend the lifespan of their equipment.

Furthermore, operators should be trained on how to use wire stripping machines safely and effectively. Proper training ensures that operators understand how to operate the machine correctly, follow safety protocols, and troubleshoot common issues that may arise during operation. By investing in training programs for machine operators, industrial businesses can improve overall efficiency, reduce the risk of accidents or injuries, and maintain a high standard of quality in their wire-stripping processes.

Maintenance and Safety Considerations for Wire Stripping Machines

Maintenance and safety considerations are essential aspects of operating wire stripping machines in industrial settings. Regular maintenance is necessary to keep these machines in optimal working condition and prevent malfunctions or breakdowns that can disrupt production schedules. This includes inspecting the machine for signs of wear or damage, replacing worn-out parts as needed, and performing routine cleaning and lubrication tasks.

In addition to regular maintenance, safety protocols should be established and followed to ensure the well-being of machine operators and other personnel working in the vicinity of wire stripping equipment. This includes providing appropriate personal protective equipment (PPE) such as gloves, eye protection, and hearing protection to minimize the risk of injury during operation. Operators should also be trained on safe operating procedures, emergency shutdown protocols, and how to handle potential hazards associated with wire stripping machines.

Furthermore, it is important to adhere to industry regulations and standards related to machine safety and workplace health. This may involve conducting regular inspections of wire stripping equipment to identify potential safety hazards or compliance issues. By staying informed about regulatory requirements and implementing best practices for maintenance and safety, industrial businesses can create a secure working environment for their employees while maximizing the efficiency and reliability of their wire stripping operations.

Future Trends in Wire Stripping Machine Technology

The future of wire stripping machine technology is marked by advancements in automation, precision, and sustainability. As industries continue to prioritize efficiency and environmental responsibility, manufacturers are developing innovative wire stripping machines with enhanced automation features such as robotic arms, artificial intelligence (AI) integration, and remote monitoring capabilities. These advancements aim to streamline wire-stripping processes, improve accuracy, and reduce labor costs while meeting the growing demand for sustainable material recycling solutions.

In addition to automation, future trends in wire stripping machine technology also focus on precision engineering to accommodate a wider range of wire sizes and insulation types. Advanced cutting mechanisms with adjustable settings allow for greater flexibility in processing various materials without compromising quality or efficiency. This enables industrial operations to handle diverse wire-stripping requirements with a single machine, reducing the need for multiple equipment setups.

Furthermore, sustainability is a key driver of innovation in wire stripping machine technology. Manufacturers are developing eco-friendly solutions that minimize energy consumption, reduce material waste, and optimize resource recovery during the wire-stripping process. This includes the integration of energy-efficient components, waste-reducing design features, and improved material separation techniques that support circular economy principles.

Overall, future trends in wire stripping machine technology are focused on delivering advanced automation capabilities, precision engineering solutions, and sustainable practices that align with the evolving needs of modern industries. By embracing these technological advancements, industrial businesses can enhance their operational efficiency, reduce environmental impact, and stay competitive in an increasingly demanding market landscape.

In conclusion, wire stripping machines play a crucial role in industrial operations that involve processing electrical wires and cables. These machines offer a wide range of benefits including increased efficiency, cost savings, environmental sustainability, and improved workplace safety. When choosing a wire stripping machine for your industrial operation, it is important to consider factors such as processing volume, material specifications, available space, level of automation required, and operational preferences. By following tips for efficient operation, maintaining equipment properly, prioritizing safety considerations, and staying informed about future trends in technology, industrial businesses can optimize their wire-stripping processes for long-term success in a competitive market environment.

If you’re interested in learning more about wire stripping machines, you should check out this article on unicovermouth.com. This website offers a comprehensive guide to wire stripping machines, including reviews, buying guides, and tips for using them effectively. Whether you’re a professional electrician or a DIY enthusiast, this article will provide valuable information to help you choose the right wire stripping machine for your needs.

FAQs

What is a wire stripping machine?

A wire stripping machine is a device used to remove the insulation from electrical wires in order to recycle the copper or aluminum inside.

How does a wire stripping machine work?

A wire stripping machine works by using a blade to cut through the insulation of the wire, while leaving the metal core intact. The machine then pulls the insulation off the wire, leaving the metal core exposed.

What are the benefits of using a wire stripping machine?

Using a wire stripping machine can save time and labor when stripping large quantities of wire. It also allows for the recycling of the metal core, reducing waste and providing a source of valuable materials.

What types of wire can be stripped with a wire stripping machine?

Wire stripping machines can be used to strip a variety of insulated wires, including copper, aluminum, and other metals.

Are there different types of wire stripping machines?

Yes, there are manual, electric, and pneumatic wire stripping machines available. Manual machines require hand cranking, while electric and pneumatic machines are powered by electricity or compressed air, respectively.

What safety precautions should be taken when using a wire stripping machine?

It is important to wear safety goggles and gloves when using a wire stripping machine to protect against potential injury from flying debris or sharp edges. Additionally, it is important to follow the manufacturer’s instructions and guidelines for safe operation.